Precision and quality from tradition (9th May '17)

Download (PDF - 329 KB)

Our successful

business history dates back to 1886. Since our establishment, “von den Steinen”

manufactures quality tools, and since 1918, primarily for the industrial separation-

and processing technology. The long-standing tradition and accompanying know-how

allow us to implement customer-specific tasks and requirements optimally and

economically.

Thanks to their precision and high quality, our products are valued and

requested worldwide. “von den Steinen” offers circular knives and tools for

precise, fast, gentle on materials, and economical processing for various

materials and applications.

Customer satisfaction is our first priority, and our aim is to offer you highest quality, innovative products, as well as comprehensive services. “von den Steinen” stands for optimal customer service from the very beginning on. We will guide you from individual consulting at the start of a project, over requirement-specific product development and problem solutions, up to tool and machine setup at your premises. Competent and individual advice as well as numerous service features ensure highest customer satisfaction.

Since 1992, we are a wholly-owned subsidiary of the “Friedr. Dick GmbH & Co. KG” corporate group in Deizisau, Germany. Today, more than 40 employees work at our branch in Remscheid, Germany. The combination of traditional craftsmanship and modern manufacturing processes are the reason for the worldwide success of our company and its products.

Our products

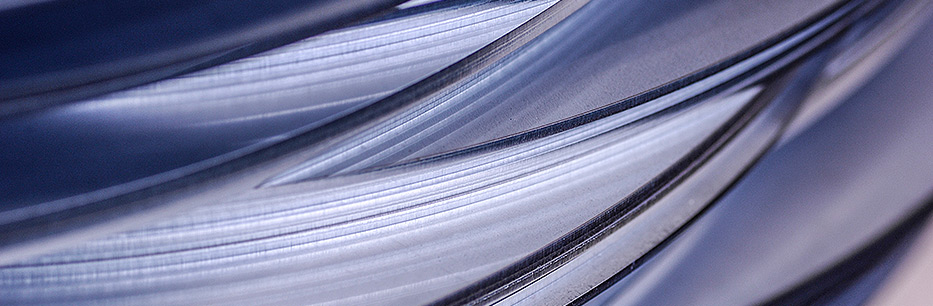

Circular knives and machine knives are indispensable for the individual

processing of various materials and fabrics, as most mass goods can only be

split, disassembled and cut economically with machines. The blades used in processes

like this are stressed on a near-permanent basis, and have to have the highest

possible lifetime in order to be economically efficient. Thus, the proper

choice of blade shape and corresponding cutting edge, as well as premium material

quality and processing are of utmost importance.

Against this background, we at

“von den Steinen” use the exact structural shapes, materials and coatings

dependent on our customers’ requirements, in order to guarantee the highest

possible durability and longest usage of our blades.

The processing of food demands a cautious compliance with hygiene

regulations.

The circular knives used there must live up to the highest demands of lifetime,

durability and quality as well.

Therefore, we exclusively use stainless steel

for products of the food industry.

Knives have to be low-wear and resistant to pitting corrosion even under persistent

usage, frequent purification and extreme conditions

(e.g. processing of fish on

fishing fleets).

We develop and manufacture our products with focus on this standards, as we

are convinced that we will always be able to

improve our products and ourselves.

Resting on our oars? Not our philosophy.

That is why we have made huge efforts in research and development in 1996,

with the objective to live up to the standards of the fishing industry.

We have

gained massive knowledge regarding processing of stainless steel during this

period of time. Products of the food industry are also rated

considerably high

at “von den Steinen”. This is the reason we pay particular attention on the

consistent quality of our knives in this value chain.

They

are therefore suitable for usage under extreme conditions, e.g. in the field of

deep-sea fishery. Even the constant contact with saline sea air and sea water

will not affect our products at all. In order to meet and even surpass high

quality standards like this with our knives and tools, we constantly develop our

products further.

We take advantage of this accumulated knowledge in the

production of our circular knives for cutting kebab, gyros and suchlike. As the

slicers for kebab came onto the market, first of those got equipped with our knives

right away. We have continuously monitored the progression of this industry and

took part in a lot of new product developments.

We have addressed reduction in

friction for kebab cutting as well as minimization of noise for gyros cutting

with toothed circular knives. Moreover, a sharpening device for circular knives

on slicers has been developed (DiaReno).